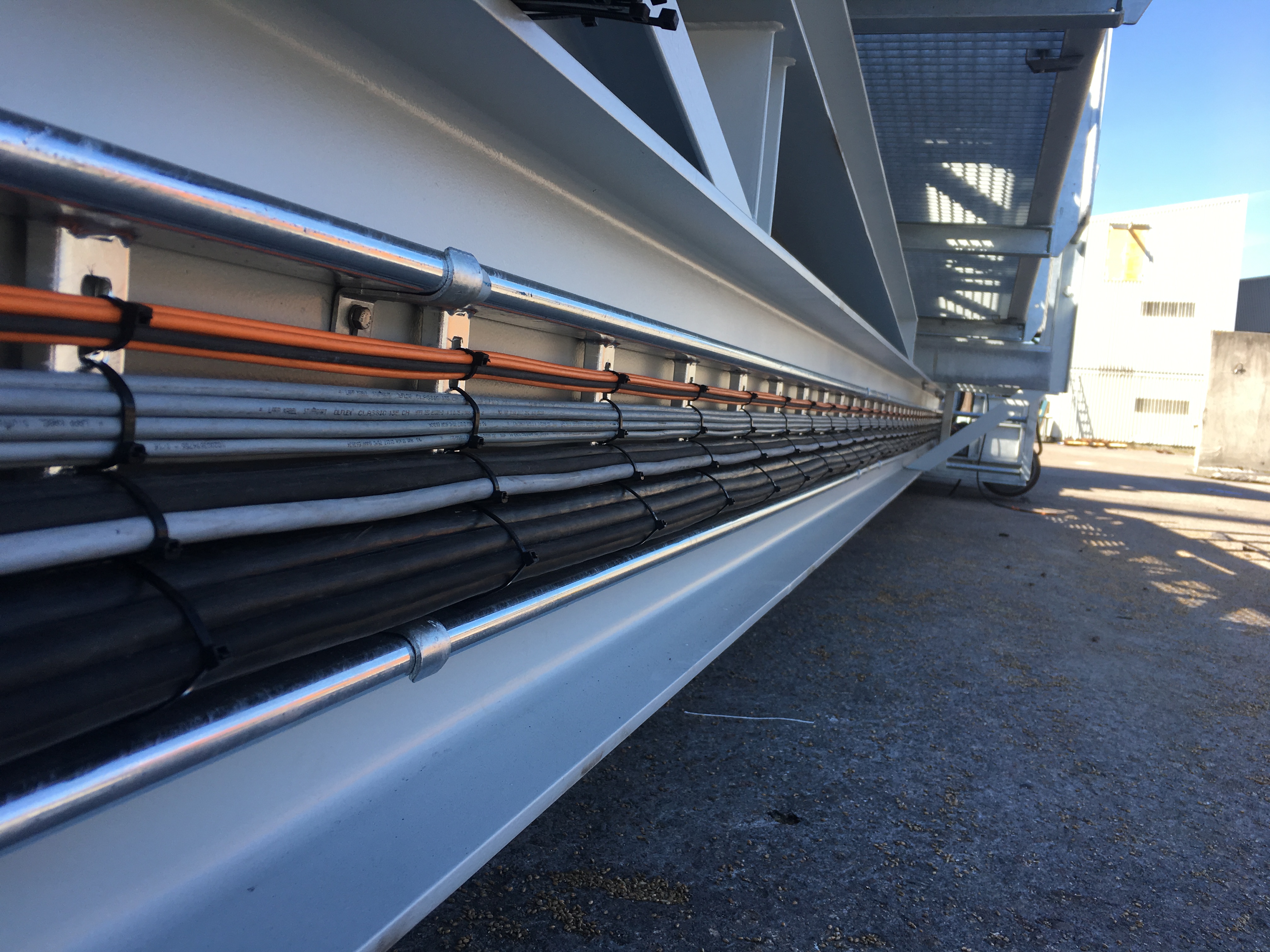

CABLE SUPPORT SYSTEMS, CABLE TRAY SYSTEMS AND CABLE CONDUITS

Cable support systems, cable tray systems and cable conduits are available in a lot of shapes and sizes. These products all differ from one another and have distinctive features: construction reliability, product finishing and the simplicity in processing.

Does your building need corrosion proof materials? Do you choose sendzimir galvanised steel, electrolytically galvanised steel or hot-dipped galvanised steel? Or are aluminium, nickel plated, stainless steel or synthetic materials better? For the perfect finish of your cables and wires you need to make a decision on which clamps, grips, bends, lids, attachments, couplings and riser conduits to use.

As an installation company Beemster Electrical Solutions can assist you in making the perfect selection. From complete tubing packages to cable ladders with all related attachment material. When long lengths are required we deliver a strong, stable and sleek construction after installation.

CPR FIRE CLASSIFICATION OF CABLES AND ELECTRICAL WIRES

As per 1 July 2016 the CPR is the standard for fire classification of cables and electrical wires in constructions. In Europa CPR is known as the EN 50575 (CPR) standard. The abbreviation stands for Construction Products Regulation. In the Netherlands the NEN 8012 standard was drawn up as a fire rating standard. The idea of the regulation is to create more uniformity and to clarify the reaction to fire of cables.

Manufacturers, technicians and distributors had one year to comply with the new regulation. From 1 July 2017 only CPR certified cables must be applied for permanent installations. Although not all installation companies know about this standard, a number of cable types can no longer be applied.

WHAT IS CPR?

The fire classification denotes the flame propagation and heat emission, smoke emission, falling parts and acidity. The CPR fire classification is also defined by the difference in smoke emissions between halogenated (PVS) installation cables and halogen-free cables. The fire classification is related to the risk situation of a building. A good insight makes it easier to choose the right cable for a building.

Manufacturers must execute fire tests to ensure that their products have the correct fire classification. They also have to draw up a CE mark and a Declaration Of Performance (DOP) op. Distributors must ensure that all cables have the proper marks in order that technicians and advisors can choose and use the applicable cable.

The NEN 8012 standard denotes four classes of fire (in incremental performances): Eca, Dca, Cca en B2ca. There are also separate classifications for the performance in relation to smoke emission (s), burning falling parts (d) and acidity (a).

The combination of these performances provides the following classifications for electrical cables in constructions:

· Low fire risk (fire class Eca)

· Medium fire risk (fire class Dca-s3, d2, a3)

· High fire risk (fire class Cca-s1, d1, a1)

· Extreme high fire risk (B2ca-s1, d1, a1).

Machine cables are not subject to CPR, even when machines require a lot of space in a building. The cables for the building-related (permanent) installations, such as heating installations, ventilation installations, cooling installations and permanent lighting are subject to CPR. NEN 8012 stipulates the applicable classification.

The engineers, project managers and the mechanics of Beemster Electrical Solutions advise you in your choice. For more information, please feel free to contact us without any obligation.

Feel free to contact us directly:

Sales team

E: info@beemster.nl

T: +31 (0)72 571 1282

Know what you want? Fill out our contact form:

NL

NL