SCADA SYSTEMS CREATE INSIGHT

SCADA collects, processes, visualizes and sends signals of various machines in industrial systems. SCADA is the abbreviation for Supervisory Control And Data Acquisition. A SCADA-system contains electrical hardware and software to facilitate machine control.

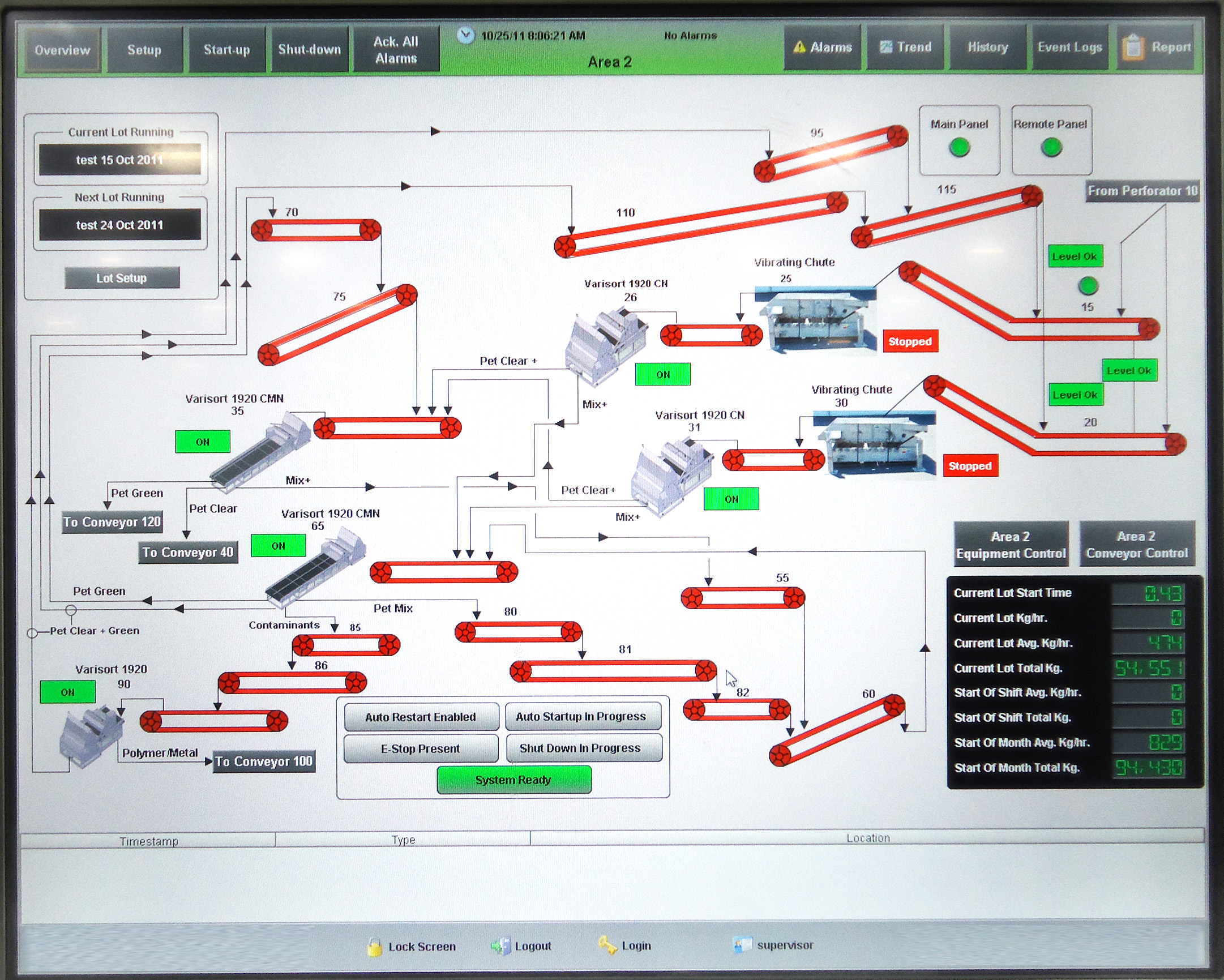

By visualizing control signals it is easier for operators to control machines and process installations. The software collects, reads and exchanges measurement data. Measurement data are processed in reports and offer insight in processes. Also, this simplifies alarm alert when installed setting of machines and systems are exceeded.

The SCADA-system is used a lot in factories to control manufacturing processes. The software reads data which can be communicated to a PLC.

ADVANTAGES OF MANUFACTURING PROCESS VISUALIZATION WITH SCADA

Process visualization with SCADA provides a clear view of the factory machines on screen or display. Moreover, the operator can monitor velocities, capacities and quantities of processed materials. In this way, the operator gains a lot information about the operational manufacturing process and productivity. He can fine-tune the settings, where necessary.

When required, the visualization can also be displayed on a screen in the switch cabinet, a separate screen or on a computer. Users can distinguish and control the different machines easier by the images and drawings of the machines on the panel.

In the reports you can find the obtained results. The trending module shows the history and is displayed in a chart, which makes it easier to retrace the reasons why process failures were caused.

DIFFERENCE BETWEEN SCADA AND DCS

The difference between SCADA and DCS is best explained by first understanding the meaning of a DCS system. There is some overlap. DCS is the abbreviation for Distributed Control System and, as is SCADA, part of a manufacturing system. It is used to monitor, control and check processes. As in SCADA systems, DCS systems ensure that product processes run smoothly and machines work according to the desired settings.

The differences

• With a DCS the process runs independently without an operator. However, fine-tuning is possible, where necessary. Whereas DCS-systems control process statuses and trends, SCADA-systems operate according to the eventualities that occur in a process. The SCADA-system focuses on data collection and data comparison and, subsequently, provides feedback to the operator. A DCS-system focuses on the controlled process and monitors each step during the operation. In short, SCADA is an event driven system, whereas DCS monitors for an eventual setting change to occur.

• A Distributed Control System is often applied for controlling activities at a single location. SCADA systems are used to control multiple locations. A SCADA network is created by linking multiple locations with a DCS-system to each other.

The terms are often used interchangeably, which is understandable, because of the overlapping functionalities in monitoring and controlling of manufacturing processes. The main difference is that SCADA is mainly applied in situations where the control centre is situated at an external location. So it can happen that you work with a DCS-system, but it is referred to as SCADA in your branch.

The specialists at Beemster Electrical Solutions BV are more than happy to provide information about these systems or adapting existing systems. Please feel free to contact us without any obligation.

DIFFERENCE BETWEEN HMI AND SCADA

HMI is the abbreviation for Human Machine Interface and includes any device or software that allows you to interact with a machine. A HMI converts input of users to signals in order to make the machine operate as desired. Conversely, the user is supplied with the required data for controlling the machine.

The user enters data by using his cursor, keyboard or microphone. The user reads the data on a computer or TV screen. In this way operators can control whether the devices are working within the set margins. The data performances of the device can be forwarded from the operation screens to a PLC which, subsequently controls the device according the required actions.

However, a SCADA-system manages the entire manufacturing process or factory and provides a complete monitoring system. A HMI cannot function without a SCADA-system. A HMI is the actual part of a SCADA-system which is used by the operator. Examples of Human Machine Interfaces are an operator panel or text display for the local operation of a machines or several machines.

For operators HMI’s are more visible than SCADA. A SCADA-system needs to registrate a lot of data to manage an entire process. However, the primary task of a HMI is to directly operate a device (stand-alone).

INSIGHT IN MANUFACTURING PROCESSES BY COMBINING DATA

There are many types of software and hardware available for the visualization and registration of data in manufacturing processes. The greatest advantage of data visualization and registration is that fine-tuning of entire processes is made simple.

The operator of a manufacturing process can easily detect the status of operating devices within the system. Data registration makes it possible to detect failures and (automatically) fine-tune machines. Another advantage is the centralized control of devices.

Siemens is market leader in the production of high-quality automation software and hardware. A lot of organisations use Simatic PCS7 and WinCC hardware and software for automation. These Process Control Systems (PCS) offer a wide range of automation systems and offer the possibility to select the optimum solution.

Beemster Electrical Solutions is conversant with Siemens systems and has developed the specialism to solve complex situations by applying these systems. For more information about our systems, please feel free to contact us.

Feel free to contact us directly:

Sales team

E: info@beemster.nl

T: +31 (0)72 571 1282

Know what you want? Fill out our contact form:

NL

NL